.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

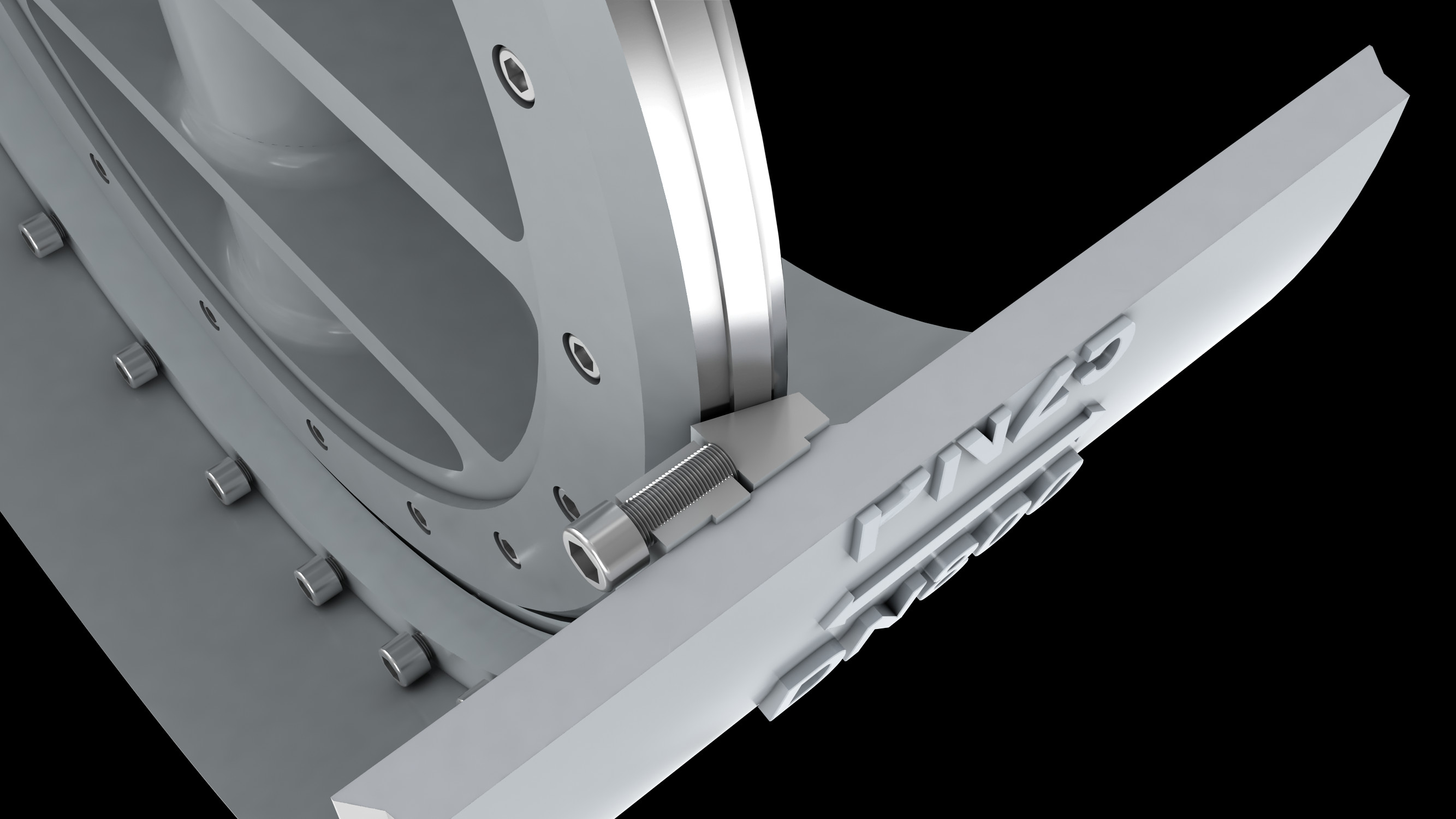

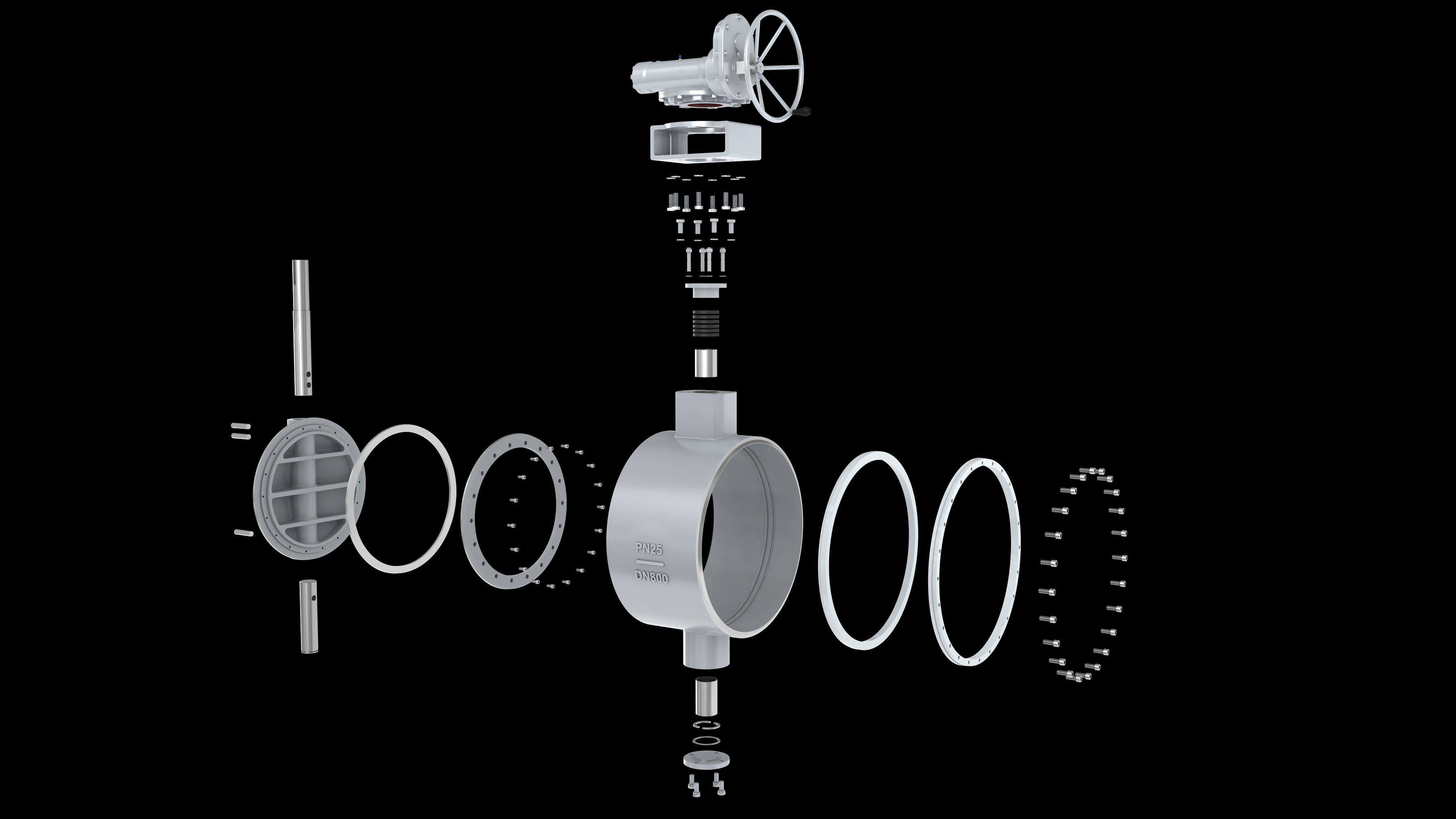

Butt Weld Triple offset Butterfly Valve

Overview

YUMING Weld type Triple offset butterfly valve could provide both laminated sealing and fully metal sealing. Forged body is to be applied for this series, it could avoid internal looseness that cannot be seen during the casting process and the defects of body strength and axial force by plate welding process.

Structure

Triple offset butterfly valve add a third angular eccentric based on double eccentric structure. The third offset is consist of an certain angle between center line of valve body and conical seat sealing face, it ensure the sealing ring of the disc can be separated or touched with seat rapidly so that friction and squeeze between seat and sealing ring will be eliminated.

Friction free design

The use of triple eccentric structure reducing the friction during switching between the sealing surface of the disc and valve body, so that the disc can quickly disengage the valve seat when the triple eccentric butterfly valve is opened or closed.

Low opening torque

This serial uses the Radial Dynamically Balanced Sealing System,by means of optimized design, the forces undertaken on both sides for the butterfly disc inlet and outlet become approximately balanced so as to effectively lower the valve opening torque.

Lubricated bearing

In order to reduce the operation torque and avoid lock of stem under frequently open and close, a customized self-lubricating bushing has been applied.

Material

Seal ring of laminated type is made of stainless steel plate with graphite/ carbon fiber/ PTFE etc. Compare to the rubber asbestos plate material, our adopting material is more wearable, anti-flush, reliable and better for environmental.

Seat ring of metal sealed butterfly valve is made of forged alloy steel which has the advantages of anti-scour, wear-resistance, high pressure and temperature resistance and long life span.

Trim material is made of high quality stainless steel, it could avoid the corrosion problem after long time using.

Application

District energy : Thermal power station, heat exchange station, regional boiler plant, hot-water loop, stem pipe system

Refinery : Brine, Carbon dioxide vapor, propylene plant, vapour system, propylene gas, ethylene plant, ethylene cracking device, coking plant

Nuclear power plant : containment isolation, seawater desalination system, brine system, core spray system, pump isolation

Thermal power generation : condenser cooling, pump and steam extraction isolation, heat exchanger, condenser cooling isolation, pump isolation

Low temperature : liquid gas, liquefied natural gas systems, oilfield recovery systems, gasification plants and storage equipment, liquefied natural gas transportation systems

Pulp and paper : steam isolation, boiler water, lime and mud

Oil refining : Oil storage isolation, air supply valve, desulfurization system and waste gas processor, flare gas, acid gas isolation, FCCU

Natural gas

| Body | WCB, A105, WC6, WC9, CF8, CF8M, CF3, CF3M, 4A, 5A, CN7M, C95800, etc. | |||

| Butterfly plate | WCB, WC6, WC9, CF8, CF8M, CF3, CF3M, 4A, 5A, CN7M, C95800, etc. | |||

| Stem | 17-4PH (630), 20CR13 (420), XM-19, 329, F51, F53, etc. Hard chrome plating, nitriding, mirror grinding | |||

| Seat | Body surfacing D507Mo, surfacing 304, surfacing 316, surfacing hard alloy, surfacing special stainless steel, etc. | |||

| Independent ring 20CR13, F304, F304L, F316, F316L, F51, F53, etc. | ||||

| Sealing ring | Multi-layer 20CR13+graphite/PTFE, 304+graphite/PTFE, 316+graphite/PTFE, 2507+PTFE, carbon fiber, etc. | |||

| Head-to-head SS304, SS316, SS304L, SS316L, 2205, 2507, etc. | ||||

| Seat fixed three open ring | 20CR13, F304, F304L, F316, F316L, F51, F53, etc. | |||

| Butterfly plate pressure ring | 20CR13, F304, F304L, F316, F316L, F51, F53, etc. | |||

| Bracket | Carbon steel, Stainless steel, etc. | |||

| Bolts and nuts | Corresponding material with internal parts | |||

| Filler | Flexible graphite、PTFE | |||

.jpg)

| DN | L | ∅D | ∅D1 | H | L1 |

| 100 | 190 | ∅99 | ∅108 | 365 | 123 |

| 125 | 200 | ∅124 | ∅133 | 415 | 150 |

| 150 | 210 | ∅150 | ∅159 | 430 | 178 |

| 200 | 230 | ∅205 | ∅219 | 580 | 240 |

| 250 | 250 | ∅259 | ∅273 | 660 | 290 |

| 300 | 270 | ∅311 | ∅325 | 735 | 340 |

| 350 | 290 | ∅363 | ∅377 | 780 | 395 |

| 400 | 310 | ∅412 | ∅426 | 885 | 450 |

| 450 | 330 | ∅464 | ∅478 | 965 | 510 |

| 500 | 350 | ∅514 | ∅530 | 1050 | 560 |

| 600 | 390 | ∅612 | ∅630 | 1195 | 660 |

| 700 | 430 | ∅700 | ∅720 | 1360 | 765 |

| 800 | 470 | ∅796 | ∅820 | 1500 | 870 |

| 900 | 510 | ∅896 | ∅920 | 1665 | 970 |

| 1000 | 550 | ∅992 | ∅1020 | 1825 | 1070 |

| 1200 | 630 | ∅1192 | ∅1220 | 2080 | 1280 |

| 1400 | 710 | ∅1388 | ∅1420 | 2340 | 1490 |