A gas welded ball valve is a valve used to control the flow of gas and is characterized by a fixed connection between the ball and the valve body through a welding process, resulting in a tight seal and fluid control. This type of ball valve is suitable for use in a variety of gas piping systems, including domestic, commercial and industrial applications.

- Tight Welded Connection: The ball and valve body are joined together through a welding process, eliminating removable connection points and ensuring a reliable seal.

- Safety: Due to the tight welded connection, the gas welded ball valve effectively prevents gas leakage and ensures the safety of the gas system.

- Fluid Control: By rotating the ball, the flow of gas can be precisely adjusted to meet different needs.

- Durability: Gas welded ball valves are often made of corrosion-resistant materials that can withstand the chemicals in the gas, increasing the durability of the valve.

- Easy Operation: Gas welded ball valves are usually equipped with a manual lever, which makes it easy for users to open and close the valve easily.

- Scope of application: Suitable for a variety of gas systems such as home gas supply, commercial buildings, industrial facilities and so on.

Gas welded ball valve is a kind of valve with tight welded connection, safety and reliability, fluid control ability, used to control the flow of gas, widely used in various gas pipeline systems.

Features and benefits

- Valves are designed with forged steel trunnion mounted.

- Floating seat.

- PMSS or metal-metal seat.

- Balls are fixed by internal mounting plate.

- Fire safe design as per standard API607/API6FA.

- Seat structure could be DBB/DIB/DBB-DIB.

- Weled by typical narrow-gap multi-layer submerged arc welding.

- Welding seams are inspected by 100% UT and hardness test.

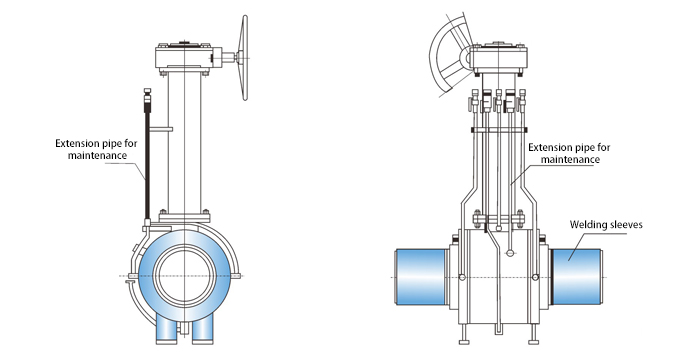

- Extension stem.

Applications

natural gas, city gas, oil field use

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)