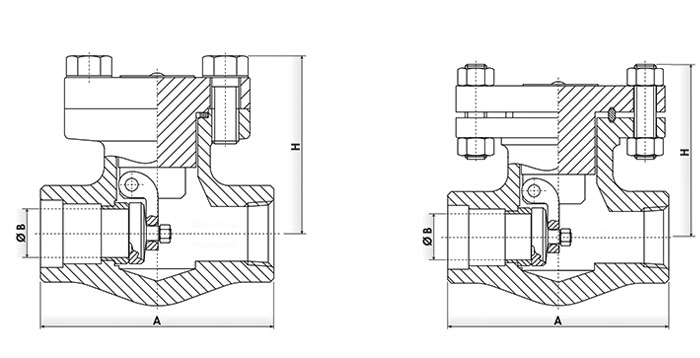

Forged Steel Check Valve

YUMING's Horizontal Piston Type Forged Steel Check Valve is available with screwed and flanged ends, featuring a heavy rugged body with a bolted cover design. Designed in compliance with API 602, BS 5352, and ASME B 16.34 standards.

It is available in end connections of socket weld, butt weld, and threaded (screwed) BSP or NPT, with pressure ratings of Class 800# and 2500#.

The YUMING piston-type horizontal lift-type forged steel check valve incorporates a self-cushioning effect, with a body-guided piston ensuring accurate return to the seat ring to achieve leak tightness.

YUMING's manufacturing range covers both regular port and standard port types of Forged Steel Check Valves.

Forged Steel Piston Lift Check Valve screws are available in a wide range of body materials, such as ASTM A 105 - Forged Carbon Steel, ASTM A 182 F 304/304L/316/316L, and ASTM A 182 F 11/22 - Alloy Steel, to suit various industrial applications.

For high-pressure and high-temperature applications, Stellited F6 face seat and disc are available.

Design & Testing International Standard of Forged Steel Check Valve Screwed

Design Standard:

- BS 5352 / API 602 / ASME B 16.34

Inspection & Testing:

- BS EN ISO 12266-I (BS 6755-I)/ API 598/ ISO 5208

StandardFace To Face Distance:

- BS 5352 / API 602 / ANSI B 16.10

End Connection:

- Screwed - Threaded End to ANSI B 1.20.1

- Socket Weld End to ANSI B 16.11

- Flanged Ends to ANSI B 16.5

Salient Features

A Compact But Extremely Sturdy Design for High Pressure & Temperature Service

Bolted Cover Design, easy to open cover

Piston Type Body Guide Disc

Assure Perfect Alignment of Disc & Seat Ring

Spring Loaded on request

Stellited F6 Disc & Seat optional

High Tensile B7/2H Fasteners

Application

Power Plants & Process Industries

Petrochemical Plants & Refineries

Cement & Fertilizers Plants

Steel Plant

Process & General Industries

Sugar Industries & Distillery Plants

Water, Steam, Gas, Oil & other Non-aggressive media

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)